Lubricant supply monitoring

GreaseCheck

Online grease monitoring helps to minimize bearing failures

The service life of the lubricant is the decisive value for the bearing life. The GreaseCheck grease sensor can be used for monitoring bearings lubricated with grease. The lubricant can be topped up or replaced in good time before damage occurs.

Your benefit:

- Up-to-date information about the condition of the grease in the bearing

- No outlay for manual sampling and analysis of grease

- Allows automated, optimized, and requirement-based relubrication

- Cost savings for fresh and used grease (sustainability)

Comprehensive reasons to use GreaseCheck

Online information about the condition of the grease optimizes relubrication and saves both time and costs for offline grease analyses

Statically, grease that is in good condition allows 25% of all bearing failures to be prevented.

Even in hard-to-reach machines and facilities, the condition of the grease can be monitored without a large outlay.

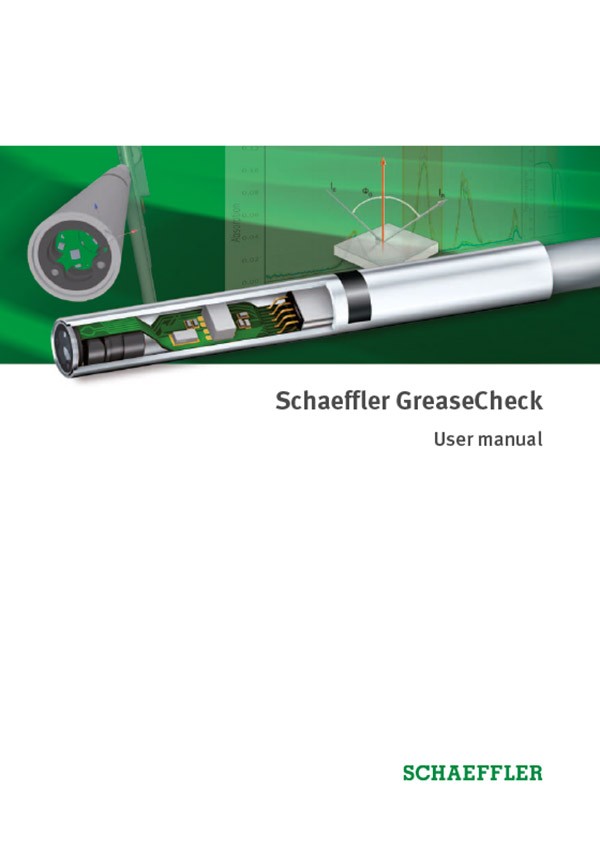

Features

- An independent, maintenance-free measuring system

- IP 67

- Interfaces: Analog, digital, and CAN bus

- Monitoring of grease’s contamination, consistency, and water content

- Small design envelope (sensor head diameter: 5 mm), suitable for a wide range of applications